Page Telephone-A Summary of IEC 60708

|

A Summary of IEC 60708

Scope

1) Conductor |

|

|

2) Insulation -Insulation material The conductor shall be covered with solid or cellular polyolefin insulation or any combination thereof. - (Polyethylene or Polypropylene) |

|

|

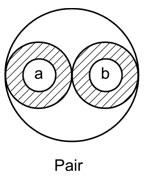

3)Cabling element A cabling element shall be – a pair of two insulated conductors twisted together and Designated wire a and wire b |

|

|

4)Stranding The cable elements shall be formed into a number of sub-units or units which can be stranded into a regular make up to produce the required number of pairs. -25 pair count The pairs shall be identified by each insulated conductor having a single colour in accordance with the colour scheme given in Annex C. Sub-units shall be identified by coloured bindings of tape or threads. Each group of sub-units making up a 25 pair count shall be identified by a common colour of bindings. |

|

|

5)Filling

6)Core protection |

|

|

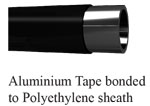

7)Sheath -General: A moisture barrier aluminium laminated polyethylene sheath construction is specified for both underground and aerial cables. This type of sheath will also provide screening. For aerial cables a figure “8” construction is specified. Circular sheath cables can also be used as aerial cables. -Sheath material : Aluminium Tape bonded to Polyethylene sheath . -Aluminium tape: The aluminium tape shall be coated on at least one side with a polymer film. The aluminium tape without the polymer layer shall have a nominal thickness of at least 0.15 mm. -Polyethylene: The polyethylene shall have a minimum carbon black content of 2.0 %. |

|

|

8)Cable protection

|

|

|

A Summary of IEC 60708 (Electrical Requirements)

LOW-FREQUENCY CABLES WITH POLYOLEFIN INSULATION AND

MOISTURE BARRIER POLYOLEFIN SHEATH

|

|

|

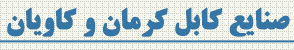

1) Electrical resistance of conductor

|

|

|

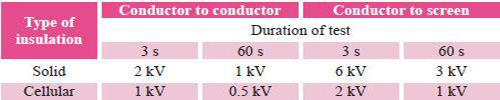

2) Dielectric strength

The dielectric strength of the insulation shall be checked on the finished cable.

The insulation shall withstand the application of a d.c. test voltage.

The test voltages for alternative durations are given in following table .

|

|

|

3) Insulation resistance

The insulation resistance at a temperature of 20 °C shall be not less than:

- for filled cables 1 500 MOhm x km

- or unfilled cables 5000 MOhm x km

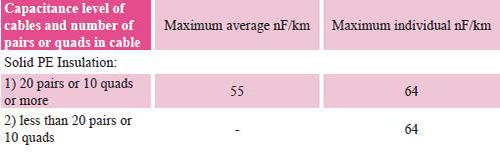

4) Mutual capacitance

The mutual capacitance shall not exceed the values given in following Table.

|

|

|

|

|

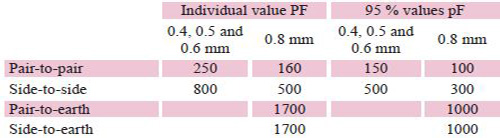

5) Capacitance unbalance

The capacitance unbalance shall not exceed the values given in following Table per 500 m length of cable:

|

|

|

|

|

*** Following Parameters aren’t applicable to A-2Y(St)2Y cables with static screen.

6) Attenuation

Attenuation values depend on cable design and should be given by the manufacturer.

Measurement method according to IEC 61156-1, 3.3.2.

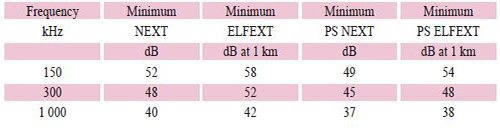

7) Near End Crosstalk (NEXT)

NEXT values are given in Table 6.

Measurement method according to IEC 61156-1, 3.3.3.

8) Equal Level Far-end Crosstalk (ELFEXT)

ELFEXT values are given in following Table.

Measurement method according to IEC 61156-1, 3.3.5.

9) Power sum (PS) of crosstalk loss

Power sum values of near-end and equal-level far-end crosstalk loss are given in following Table.

Measurement method according to IEC 61156-1

|

|

|

|

|

10) Characteristic impedance

The nominal value of characteristic impedance Z0 of the cable shall be in the range from 80 Ohms to

130 Ohms at 1 MHz, depending on the design. The maximum deviation from the nominal characteristic

impedance shall be within ±15 %.

Measurement method according to IEC 61156-1, 3.3.6.

11) Velocity of propagation

The velocity of propagation shall be >60 % at 1 MHz.

Measurement method according to IEC 61156-1, 3.3.1.

|

|