Page Telephone- A Summary of IEC 60189-2

A Summary of IEC 60189-2

Low-frequency cables and wires with PVC insulation and PVC sheath

Part 2:Cables in pairs, triples, quads and quintuples for inside installations

Scope :

This part of IEC 60189 is applicable to cables for inside installations, intended for the interconnection of the following:

– Transmission equipment;

– Telecommunications equipment;

– Equipment for data processing.

1) Conductor

- Conductor material

The conductor shall consist of annealed copper, uniform in quality and free from defects.

The properties of the copper shall be in accordance with IEC 60028.

- Type of conductor

The conductor shall consist of a single strand, circular in section.

-Conductor finish

The conductor may be either plain or tinned.

-Conductor dimensions

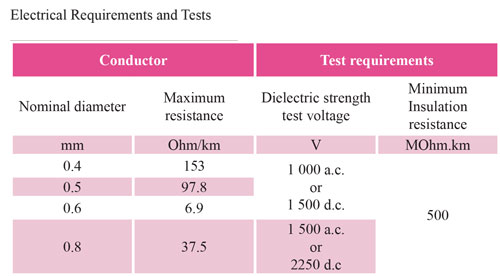

The conductor is designated by its nominal diameter. Nominal Diameters are 0.4,0.5,0.6,0.8 mm .

-Continuity of conductor

Normally the conductor shall be drawn in one piece.

In cases of necessity, joints in the conductor are permitted provided that the breaking strength of a joint is not less than 85 % of the breaking strength of the unjointed conductor.

|

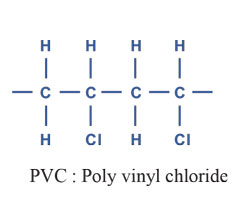

2) Insulation -Insulation material The insulation shall consist of polyvinyl chloride (PVC). -Insulation thickness The insulation shall be continuous having a thickness as uniform as possible, not less than 0.15 mm for a nominal conductor diameter up to and including 0.6 mm, and not less than 0.25 mm for a nominal conductor diameter of 0.8 mm. |

|

|

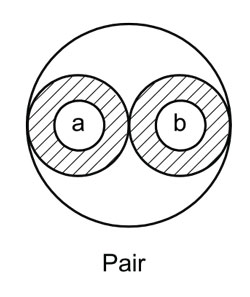

3)Cabling element A cabling element shall be – a pair of two insulated conductors twisted together and designated wire a and wire b |

|

|

4)Wrapping The core of the cable may be wrapped with a protective layer of non-hygroscopic and non- wicking material (for example, a helical or longitudinal lapping of one or more tapes with overlap or a thin continuous sheath). If a screen is provided, the protective layer shall be mandatory. |

|

|

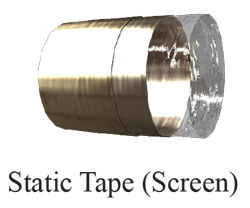

5)Screening The core of the cable may be provided with a screen. It shall consist of copper or aluminium tape of 0.04 mm minimum thickness, or of a thin tape of the same materials, of 0.008 mm minimum thickness, laminated to a plastic tape. The tape shall be wound helically or applied longitudinally round the wrapped core with an overlap of at least 20 % or 6 mm, whichever is less. One or more tinned copper wires shall be included in the cable in continuous contact with the surface of the metal tape. The wires may be of circular section or flat: the total cross-section shall be not less than 0.125 mm2. The screen may be provided with an outer protective layer of non-hygroscopic and non- wicking material (for example, a longitudinal or helical wrapping of one or more tapes with overlap). |

|

|

|

|

6)Sheath -Sheath material The sheath shall consist of polyvinyl chloride. -Colour of sheath The colour of the sheath shall be preferably grey |

|

|

|